Hello Again: Alpenfohn Nordwand Cooler Reviewed

We are going to talk about another new processor cooler with heat-pipe direct touch technology.

Air cooling systems with direct touch technology (when heat pipes have contact with the CPU’s heat-spreader) have recently been produced in larger volumes than conventional copper-sole coolers. I’ve given you the reasons in my Tuniq Tower 120 Extreme review. This technology is just simpler and cheaper to manufacture while its efficiency is high. On the other hand, Xigmatek’s Thor’s Hammer, the best representative of the direct-touch class so far, is inferior to such leaders as the Thermalright IFX-14 or Scythe Mugen 2.

The manufacturers are not taken aback by that fact, though. They go on rolling out new direct-touch products and I am going to talk about one such cooler, called Alpenföhn Nordwand, in this review.

Packaging and Accessories

There is a small cutout in the face side of the small cardboard box the Alpenföhn Nordwand is packed into. It gives you a glimpse of the cooler’s heatsink. A full-size photo of the product can be seen on the back.

Inside the cardboard exterior there is a transparent plastic blister wrap that fits the cooler and its fan tightly. A small box with accessories lies above the cooler.

The Alpenföhn Nordwand is mounted on a CPU in exactly the same way as the Tuniq Tower 120 Extreme I’ve mentioned in the Introduction, so the accessories to both products are identical in this respect. The difference is that the thermal grease comes from an obscure maker and there is no fan speed controller here (the latter is replaced with a Molex adapter). Besides, the box contains silicone pins for fans and an installation manual.

The Alpenföhn Nordwand is manufactured in China and comes at a recommended price of $64.9. It has a 1 year warranty.

Design and Functionality

This is a tower-like cooler. It measures 131x96x155 millimeters and weighs 860 grams. The heatsink does not look special at first: five nickel-plated copper heat pipes (8 millimeters in diameter) serve as the cooler’s base and a lot of aluminum plates hang on those pipes. There is also an anodized aluminum heatsink above the pipes.

The plates have a pimpled surface.

I’ve seen this kind of a heatsink texture in coolers from OCZ. This roughness serves the same purpose as the pimples on a golf ball. It helps create small whirlwinds and minimize turbulence and aerodynamic resistance. Still, I have to confess that coolers with such plates have not showed an exceptional performance before.

The aluminum plates are 0.40 millimeters thick. There are a total of 50 of them but the top plate is purely decorative, covering the ends of the heat pipes and giving the heatsink a finished look. The plates are placed 2.0 millimeters apart from each other.

The sides of the heatsink are covered by curled-down edges of the plates. The heatsink is symmetrical but there is a small arrow of a mysterious purpose on the top plate.

The user manual and the taciturn official website do not mention the arrow. Besides it, you can note an arrow-like placement of the heat pipes in the heatsink body. Of course, it would not be possible to place five 8mm pipes in a line, considering the width of the plates, but why does the arrow point inward rather than outward?

The two outermost pipes are cooled by the air from the fan the most effectively but these very pipes participate in the heat transfer with the CPU’s cap less actively than the other pipes (I will illustrate the point shortly). I guess it would be better for the pipes to be placed in such a way that the “arrow” in the top plate pointed in the opposite direction. That is, the central pipe with its two neighbors should be moved to the edges of the heatsink while the remaining two pipes should be in the center. The heatsink must be made broader in the central part for that, but this change is quite possible considering the current width of 48 millimeters.

The aluminum inserts between the heat pipes in the cooler’s base are 1.5 millimeters thick. The contact area is flat and finished well enough for an implementation of the direct touch technology.

And here is the promised illustration of how poorly the outermost heat pipes participate in the heat transfer with an LGA1366 processor.

The left photo shows that the two outermost 8mm heat pipes don’t do anything actually. They can hardly get any heat through the 1.5mm aluminum partition from the adjacent pipes. The right photo shows a better picture, yet the outermost pipes are still utilized by only 30%.

The Alpenföhn Nordwand is equipped with one 120x120x25mm fan whose frame and impeller are transparent. The seven impeller blades have a petal-like shape and rounded-off edges to minimize noise at the expense of some static pressure.

The fan is manufactured in China under the EKL brand. It is marked as SD-12025R1L4-P. The fan is PWM-controlled in a range of 850 to 1500 RPM. It is declared to have a maximum noise of 21dBA and an airflow of 53.9CFM. The cooler’s static pressure is not declared in the specs. The fluid dynamic bearing is guaranteed to work for 30,000 hours or over 3.4 years continuously. The fan rotor’s diameter is 40 millimeters while the 4-pin cable is 330 millimeters long.

The fan is fastened in the heatsink with four silicone pins. One end of each pin goes into the heatsink and another, into the fan.

This fastening mechanism seems to be optimal when it comes to minimizing the noise of the fan. There were as many as 11 such pins included with my sample of the cooler although the maximum number you need to install two fans is 8 pins. The remaining ones can be used as spare parts.

When I installed the fan on the heatsink, it turned out that there was a 13mm gap between them in the center. And when the fan was working, a large portion of its airflow was wasted through that gap without doing anything useful in terms of cooling. Therefore I will try to seal the gap with a piece of scotch tape during my tests and see if the cooling efficiency improves.

Compatibility and Installation Tips

As I wrote above, the Alpenföhn Nordwand is equipped with the same fasteners as the Tuniq Tower 120 Extreme, so I won’t discuss them here. I can only add that the distance from the mainboard to the cooler’s bottom plate is 43 millimeters.

The cooler is 3-4°C better in this position than if you turn its heatsink by 90 degrees counterclockwise. The reason is obvious if you compare the prints of the CPU’s heat-spreader on the cooler’s base that have been shown above.

The fan of the Alpenföhn Nordwand has four blue LEDs that create a soft highlighting inside the system case.

Testbed and Methods

We are going to test the cooling efficiency of Alpenföhn Nordwand inside a closed system case with the following configuration:

- Mainboard: ASUS P6T Deluxe (Intel X58 Express), LGA 1366, BIOS 1702;

- Chipset cooler: Scythe Mini Kaze 50 mm (1000 RPM);

- Processor: Intel Core i7-920, 2.67 GHz, 1.25 V, 4 x 256 KB L2, 8MB L3 (Bloomfield, C0);

- Thermal interface: Tuniq TX-2;

- Graphics card: XFX Radeon HD 5750 1 GB GDDR5, 700/4600 MHz;

- Memory: DDR3 3 x 2 GB OCZ Platinum Low-Voltage Triple Channel (Spec: 1600 MHz / 7-7-7-24 / 1.65 V);

- System HDD: Western Digital VelociRaptor (SATA-II, 300 GB storage capacity, 10,000 RPM, 16 MB cache, NCQ) inside Scythe Quiet Drive 3.5” silencer and cooler chassis;

- System case: Antec Twelve Hundred (front panel: two Noiseblocker NB-Multiframe S-Series MF12-S1 fans at 900 RPM and Scythe Gentle Typhoon fan at 900 RPM; back panel: two Scythe SlipStream 120 fans at 900 RPM; top panel: standard 200 mm fan at 400 RPM);

- Control and monitoring panel: Zalman ZM-MFC2;

- Power supply: Zalman ZM1000-HP 1000 W (with a default 140 mm fan).

During this test session we managed to overclock our 45nm quad-core processor (with polished heat-spreader) with the multiplier set at 21x and “Load-Line Calibration” enabled to 4.01 GHz. The nominal processor Vcore was increased to 1.3625 V in the mainboard BIOS.

The memory voltage was at 1.64 V and its frequency was around 1.55 GHz (7-7-7-14_1T timings). All other parameters available in the mainboard BIOS and connected with CPU or memory overclocking remained unchanged (set to Auto).

All tests were performed under Windows 7 RTM x64 operating system. We used the following software during our test session:

- Linpack 64-bit with LinX shell version 0.6.4 – to create maximum CPU load (two test cycles, 5 Linpack runs in each cycle with 3584 MB RAM capacity involved);

- CPU-Z 1.52.2 – to monitor processor core voltage and frequency;

- Real Temp 3.46 beta – to monitor the processor core temperature;

- RivaTuner 2.25 alpha build 9 – for visual control over temperature changes (with RTCore plagin);

- Everest 5.30.1954 beta – to monitor default fans rotation speeds.

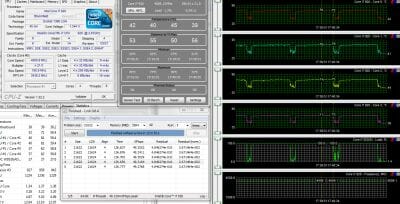

So, the complete screenshot during the test session looks as follows:

The CPU was loaded with two consecutive Linpack test runs with the settings as indicated above. The stabilization period for the CPU temperature between the two test cycles was about 8-10 minutes. We took the maximum temperature of the hottest processor core of the four for the results charts. The ambient temperature was checked next to the system case with an electronic thermometer with 0.1 °C precision that allows monitoring the temperature changes over the past 6 hours. During our test session room temperature was at 23.6-24.0 °C.

All super-coolers will now be compared against the leading air-cooling solution Noctua NH-D14. Besides it, the best cooler with direct touch technology, the Thor’s Hammer from Xigmatek, is included into the comparison.

Besides its default fan, the Alpenföhn Nordwand was tested with one and two Thermalright TR-FDB-2000 fans working quietly at 1050 RPM as well as at a full speed of 2040 RPM (one fan for intake and another for exhaust). The other two coolers were tested with the same fans.

Cooling Efficiency Tests

Dependence of Cooler Efficiency on Fans Number and Rotation Speed

In this test session the maximum frequency of the Intel processor was limited by the performance of the Alpenföhn Nordwand cooler with one standard fan at 600 RPM. It was 3885 MHz at a voltage of 1.325 V. I also tested the cooler with two Thermalright TR-FDB fans. The fan speed was adjusted with a step of 200 RPM (±20 RPM). The side panel of the system case was open during the tests. Here are the results.

It is easy to note that the efficiency of the Alpenföhn Nordwand depends heavily on the speed and number of its fans. The CPU temperature changes by 15°C when the default fan’s speed is increased from the minimum 670 RPM to 1220 RPM. Accelerating the fan above 1400-1500 RPM is not rewarding because the fan becomes loud while the temperature does not lower much.

Besides, my supposition that the default fan of the Alpenföhn Nordwand had a low static pressure seems to be true. At the same speeds a single Thermalright TR-DBH fan ensures more effective cooling of the heatsink plates and, consequently, a lower temperature of the CPU. Adding a second Thermalright fan to exhaust the air out of the heatsink helps reduce the peak CPU temperature by 11°C at a nearly-silent 600 RPM, by 4°C at 1000 RPM and by 2°C at maximum speed.

Performance Comparison

Now let’s see how good the Alpenföhn Nordwand is in comparison with the best air cooler and with the best heat-pipe direct touch cooler.

So, the Alpenföhn Nordwand is more effective than the Xigmatek Thor’s Hammer. The new cooler is superior to its opponent by 2-4°C in every mode, which makes it the best model with heat-pipe direct touch technology. Then, it is also quite good in comparison with the Noctua NH-D14, being 3-6°C weaker with the default fan and 2-4°C weaker with the same fan(s) from Thermalright. The result is just excellent for a cooler that costs $20 less than the NH-D14!

When describing the new cooler I mentioned a 13mm gap between the fan and the heatsink. Alas, when I tried to seal the gap with stripes of scotch tape…

…the Alpenföhn Nordwand’s efficiency did not change and it delivered the same best result.

I cannot say anything special about the noisiness of the Nordwand’s default fan. The fan is identical to many other high-quality 120mm models with fluid dynamic bearings that remain quiet until 1000-1050 RPM. I did not hear any strange noises from the fan during my tests at any speed.

Conclusion

The Alpenföhn Nordwand makes it clear that the heat-pipe direct touch technology is being polished off, improving the efficiency of such coolers. Despite some minor flaws in its design, the new cooler delivers the best results among HDT coolers I have tested so far and is not far behind the absolute leader among all tested coolers. It is good that the engineers did not try to make the Alpenföhn’s fan faster than 1500-1600 RPM as such speeds usually have little practical worth. Instead, they equipped the cooler with an adequate and sufficient fan with nice-looking LED highlighting. It is a pity though that there is only one fan.

Besides high performance and low noise, the Nordwand supports multiple platforms and has a reliable fastening mechanism. Its pricing makes it competitive with today’s best air-based cooling solutions.

Taking into account its excellent performance and above listed advantages we decided to award Alpenföhn Nordwand with our Recommended Buy title.

I guess this cooler can even be improved some more. Its heat pipes might be pressed together in the base without the aluminum inserts and its heat pipes might be placed differently in the heatsink body (this would make the heatsink just a little bit larger). Two default 120mm fans would also be appropriate. I hope I will be able to test a modified version like that some day.