Scythe Ninja 3 CPU Cooler: The Legend Returns?

After a pretty lengthy break the Japanese Ninja cooler comes before us in its third reincarnation. We are also going to talk about other two new cooling solutions from Scythe: Rasetsu and Mugen 2 Rev B.

The Japan-headquartered Scythe keeps on turning out new CPU coolers. Recently we had a look at the Scythe Yasya and now it’s time for us to test the newest Ninja 3 and Rasetsu as well as the revised Mugen 2. We guess the most exciting product among them is the new model in the legendary Ninja series. The first Ninja (SCNJ-1000) provoked a sensation among overclockers and earned high popularity due to excellent performance in every operation mode. Then there were the Ninja Plus (SCNJ-1000P), Ninja Plus rev. B (SCNJ-1100P), and the mini version of the Ninja. The limited-edition Ninja Copper (SCNJ-CU1000) was but slightly superior to its aluminum counterparts and was mostly purchased by collectors. The second version (SCNJ-2000) followed three years after the original Ninja but met a much tougher market competition. What can we expect from the third version? Let’s find out right now.

Ninja 3 (SCNJ-3000)

The Scythe Ninja 3 (SCNJ-3000) comes in a medium-sized box typical of Scythe products. It is all covered with pictures of the cooler and information about it.

Inside the box the heatsink and the fan are separated by a partition. A smaller box at the bottom contains the cooler’s accessories.

There is a back-plate and a couple of wire clips for attaching one fan among the accessories. Scythe has also abandoned SilMORE and now equips its coolers with new, gray-colored thermal grease. Unfortunately, the manufacturer doesn’t reveal the specs of that thermal interface. The Scythe Ninja is manufactured on Taiwan and comes at a recommended price of $60.

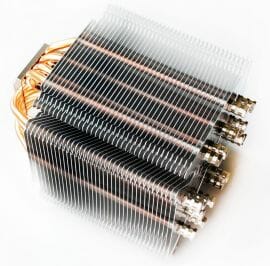

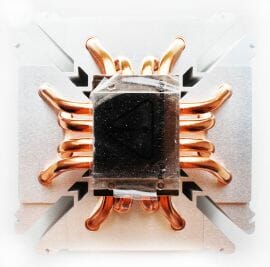

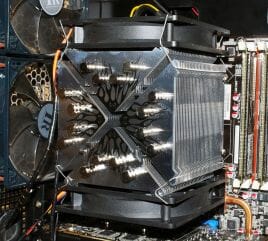

The Ninja 3 heatsink is a massive 4-section tower measuring 120x120x160 millimeters at 890 grams of weight (1040 grams with the fan).

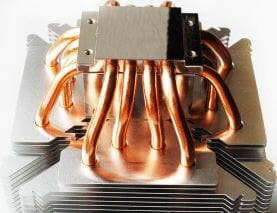

The heatsink sections rest on eight copper heat pipes, 6 millimeters in diameter, placed in two tiers. There are 36 press-fitted aluminum fins in each section plus two small fins at the bottom of each section. The fins are 0.40 to 0.45 millimeters thick and about 2.5 millimeters apart.

The total heatsink area is somewhat larger than 8500 sq. centimeters, which is much smaller than that of the Mugen 2 (10,600 sq. cm) and somewhat smaller than that of the ThermoLab Baram 2010 (8900 sq. cm). Adjacent sections of the heatsink are connected with thin aluminum bars that add rigidity to the whole arrangement.

The distance between the sections is 8 millimeters. Like with the Mugen 2, this design is referred to as M.A.P.S. (Multiple Airflow Pass-through Structure) although is implemented differently. People at Scythe seem to refer to any splitting of any heatsink into equal parts as M.A.P.S, whatever the reason for that segmentation may be. When it comes to the Mugen 2, its five separate heatsink sections with dense fins make the cooler most effective at medium and top speeds of the fans. In the Ninja 3, on its part, the distance between the fins and sections is increased, obviously to achieve high performance with low-speed fans or even in fan-less mode.

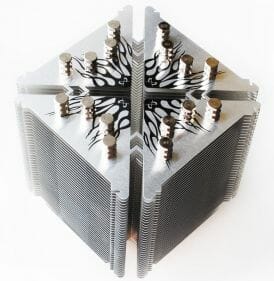

The Ninja 3 is also the first cooler from Scythe to have grooves for the four bottom-tier heat pipes:

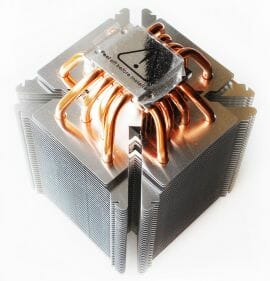

Until the Ninja 3, Scythe used to simply flatten the pipes and solder them to the flat surface of the base. Now, after some years, Scythe has come to the more effective method of ensuring thermal contact. Hopefully, not only in this model. The minimum thickness of the base below the pipes in the bottom tier is 1.8 millimeters. The pipes are soldered to the base. In the top tier of heat pipes there are grooves, too. They are made in the bottom part of the small auxiliary heatsink (48×38 mm), so the top-tier pipes just lie on the bottom-tier ones (the contact seems to be ensured through soldering, too).

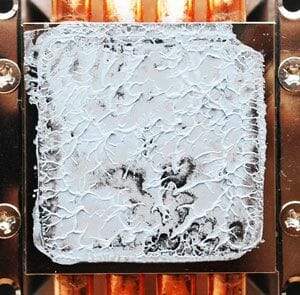

The 38x38mm nickel-plated copper base is perfectly flat and ideally finished even though there are barely visible traces of the milling machine on its surface.

It was difficult to tear the cooler off the CPU’s heat-spreader, so tight was the contact between them:

The distance from the cooler’s sole to the bottom fin of its heatsink is a mere 35 millimeters.

The Scythe Ninja is equipped with one fan. It is a Slip Stream 120 Adjustable PWM (SY1225SL12HPVC).

We explored this model and its performance in our article called “Six Coolers for Intel Core i7-980X Extreme Edition Processor”, so we won’t repeat ourselves here.

The new Ninja is universal and supports every modern platform. It is fastened by means of the included Flip Mount Super Back-Plate 2. The Ninja 3 installs on the CPU in the same way as the new-revision Mugen 2 does. And since this is the key innovation in the Mugen 2, we will discuss it in more detail below, in the Mugen 2 section of our review.

We don’t like that the Ninja 3 kit contains but one pair of wire clips for a fan. This is not the first time that Scythe shows such paltry economy. As a result, you have to use special rubber straps or purchase a couple of such clips to install a second fan.

The user manual does not indicate the best way to orient the cooler on the CPU, so we checked out both possible variants. Despite the symmetric design of the heatsink sections, the way the heat pipes lie on the CPU’s cap and the position of the bottom heatsink relative to the fans’ airflow might affect the cooler’s performance. However, we could not see any difference in performance depending on this cooler’s orientation. The two positions of the fans on the heatsink (see the photos below) proved to be equivalent, too.

The “corner” positioning of the fans was just 1°C better than the “pass-through” variant at high speeds but there was no difference at low and medium speeds. We will discuss the performance of the Scythe Ninja 3 later on. Right now let’s move on to the next new cooler.

Rasetsu (SCRT-1000)

The Rasetsu (SCRT-1000) could only be spotted on the manufacturer’s Japanese website so far, but it is not going to be limited to Japan. The cardboard package this made-in-Taiwan cooler comes in is smaller than the Ninja 3 box but carries a lot of information on itself, too.

Two pairs of fasteners, wire clips for a fan, an installation guide and Scythe thermal grease are included with the cooler.

The Scythe Rasetsu comes at a recommended price of $55 with a 2-year manufacturer’s warranty.

The first thing that strikes one after the massive Ninja 3 is how light the Rasetsu is. The fan included, the cooler weighs only 730 grams or two thirds of the Ninja 3’s weight. Well, top-design coolers like the Rasetsu have always been smaller and lighter than tower-design ones. Let’s take a look at the new product.

The outline of the Scythe Yasya heatsink can be seen easily. It looks like a Yasya tower put on its side and split into two halves which are hung on six 6mm heat pipes.

The number of aluminum fins is reduced from 54 to 52 (22+30) but they are the same thickness (0.35 mm) and the same distance apart (1.8 mm). The Rasetsu uses the Trident Multi Layer Fin structure, but does not have the mirror polish of the fins as the Yasya.

There are three heat pipes for each heatsink section. They cross each other intricately before entering the heatsink fins.

The heat pipes are not vertical but slanting in the aluminum fins which must be the consequence of technological process rather than some new feature devised by Scythe engineers. An auxiliary aluminum heatsink (64×40 mm) is installed above the heat pipes. It serves as the support for the cooler’s fasteners.

The cooler’s nickel-plated copper sole measures 47 x 50 millimeters and is 2 millimeters thick. It is finished well but not to a mirror shine.

The Rasetsu can be installed without taking the mainboard out of the system case and without using any tools. Featuring the Versatile Tool-Free Multiplatform System, it can be mounted easily on the CPU. First, you insert the fasteners into the cooler’s bottom heatsink.

The distance from the cooler’s sole to the bottom edge of the aluminum fins is 43 millimeters, so it is easy to take the cooler off by turning the plastic locks. It is unlikely to conflict with tall mainboard components.

The user manual does not tell anything about the proper orientation of the Rasetsu on the CPU although the ends of the three heat pipes are directed downward in one installation variant. Sometimes such nuances may affect a cooler’s performance. We checked out two positions.

As we found out, the Rasetsu is 4°C more effective when the heat pipes are oriented horizontally (the right photo) rather than otherwise (the left photo) although the convex CPU cap may have influenced the results. Anyway, we installed the cooler so that its heat pipes were horizontal for our tests.

Installing a 140mm fan on the Rasetsu doesn’t improve its performance.

At the same speed as the default 120mm fan, the 140mm fan cools the CPU just as effectively. By the way, the Rasetsu comes with the same fan as the Ninja 3. It is a Slip Stream 120 Adjustable PWM (SY1225SL12HPVC).

Mugen 2 rev. B (SCMG-2100)

The second revision of the Scythe Mugen 2 cooler (SCMG-2100) was released quite a long time ago but we haven’t been able to get a sample to test until now. The box is designed in such a way that your eye focuses on the letter B which denotes the new revision.

The kit includes a new back-plate and screws with nuts.The heatsink is almost the same as the heatsink of the first revision.The connecting pieces between the heatsink sections have become wider.

There are no grooves for heat pipes in the cooler’s base. Perhaps they will be implemented in the third revision. The cooler’s sole is ideally finished and flat.

The key innovation of the new Mugen 2 is the Flip Mount Super Back-Plate 2 with support for LGA1156 processors. The Ninja 3 is installed in the same way. You attach the steel fastening plates to the cooler’s base.

If you are installing the cooler on an AMD processor, the fastening plates already have threaded holes. For Intel LGA775, LGA1156 and LGA1366 processors you use the same fastener and insert figured pins into the openings and fix them with nuts.

Now you don’t have to unfasten the default back-plate from the mainboard because the cooler’s back-plate wraps the latter (and the back-plate of the Ninja 3 just lies above the default back-plate).

The cooler is secured with screws on the reverse side of the PCB. It is easier to turn the cooler upside down and put the mainboard on it.

The pressure is high and the steel fastening is absolutely reliable.The Mugen 2 should be oriented in such a way that its heat pipes ran across the CPU (as in the right photo).

In this position the top temperature of the hottest core of our LGA1366 processor was 3°C lower than when the heat pipes ran along the heat-spreader. Things may be different with AMD processors but we didn’t check this out.

The Scythe Mugen 2 revision B comes at a recommended $60 but its retail price can be as low as $50.

Testbed and Methods

Since it was extremely hot outside and we also had a top cooler participating in our today’s test session, we ran all tests inside a system case with a removed side panel. here is our testbed configuration:

- Mainboard: ASUS P6T Deluxe (Intel X58 Express, LGA 1366, BIOS 2101);

- Processor: Intel Core i7-980X Extreme Edition, 3.33 GHz, 1.225 V, 6 x 256 KB L2, 12 MB L3 (Gulftown, B1);

- Thermal interface: Arctic Cooling MX-2;

- Graphics card: ATI Radeon HD 5770 1 GB GDDR5 128 bit, 850/4800 MHz;

- Memory: DDR3 3 x 2 GB OCZ Platinum Low-Voltage Triple Channel (Spec: 1600MHz / 7-7-7-24 / 1.65 V);

- Sound card: Auzen X-Fi HomeTheater HD;

- System drive: OCZ Agility EX SSD (SATA-II, 60 GB, SLC, Indillinx, firmware v1.31);

- HDD for games and programs: Western Digital VelociRaptor (SATA-II, 300 GB storage capacity, 10,000 RPM, 16 MB cache, NCQ) inside Scythe Quiet Drive 3.5” silencer and cooler chassis;

- Backup HDD: Western Digital Caviar Green WD10EADS (SATA-II, 1000 GB, 5400 RPM, 32 MB, NCQ);

- System case: Antec Twelve Hundred (front panel: three Noiseblocker NB-Multiframe S-Series MF12-S1 fans at 960 RPM; back panel: two Thermalright X-Silent 120 fans at 960 RPM; top panel: standard 200 mm fan at 400 RPM; side panel removed);

- Control and monitoring panel: Zalman ZM-MFC2;

- Power supply: Zalman ZM1000-HP 1000 W (with a default 140 mm fan).

Keeping in mind very high ambient temperature, processor overclocking was limited by the least efficient cooler of our today’s testing participants in its quiet mode. As a result, we managed to overclock our six-core processor (with protuberant heat-spreader) with the multiplier set at 25x and “Load-Line Calibration” enabled to 4.2 GHz. The nominal processor Vcore was increased to 1.34375 V in the mainboard BIOS.

Turbo Boost and Hyper-Threading technologies were disabled during our test session. The memory voltage was at 1.64 V and its frequency was 1.68 GHz (8-8-8-16_1T timings). All other parameters available in the mainboard BIOS and related to CPU or memory overclocking remained unchanged.

All tests were performed under Windows 7 Ultimate x64 operating system. We used the following software during our test session:

- Linpack 64-bit with LinX shell version 0.6.4 – to create maximum CPU load (5 Linpack runs in each cycle with 4096 MB RAM capacity involved);

- CPU-Z 1.55 x64 – to monitor processor core voltage and frequency;

- Real Temp GT 3.59 Beta – to monitor the processor core temperature;

- CPU-Tweaker 1.5 – to visually monitor temperatures and frequencies using graphics.

The CPU was loaded with two consecutive Linpack test runs with the settings as indicated above. The stabilization period for the CPU temperature between the two test cycles was about 8-10 minutes. We took the maximum temperature of the hottest CPU core for the results charts. Moreover, we will also provide a table with the temperature readings for all cores including their average values. The ambient temperature was checked next to the system case with an electronic thermometer with 0.1 °C precision that allows monitoring the temperature changes over the past 6 hours. The room temperature during our test session varied between the annoying 30.6-31.1 °C.

The three new coolers will be compared against the recently reviewed Scythe Yasya.We are also going to include the results for ThermoLab Baram-2010, because this is one of the best coolers of the same type and structure.

All tower coolers were tested with one and two fans Slip Stream 120 Adjustable PWM (SY1225SL12HPVC) fans at 800, 1200 and 1900 RPM. Scythe Rasetsu cooler was only tested with one fan, but in the same speed modes. Here I would like to point out that on Scythe coolers Slip Stream fans are just as good as Thermalright TR-FDB fans we normally use, which is however, not true for the other manufacturers’ cooling products.

Cooling Efficiency

You can view the results of our tests as a table and in the following diagram.

Let’s first analyze the performance of the coolers with one fan only. As you can see, the Rasetsu offers the lowest performance in today’s test. Despite the open side panel of the system case, this top-design cooler is inferior to the tower-design ones, and the difference is sometimes considerable. On the other hand, the Rasetsu should be given credit for coping with an overclocked six-core CPU under such extreme conditions.

When tested with one fan, the four tower-design coolers are always changing places, depending on the speed of that fan. For example, the ThermoLab Baram 2010 is the worst one at 800 and 1200 RPM but beats the others at 1900 RPM (we could expect this because the Baram 2010 has the densest pack of fins and, despite its thought-through heatsink design, depends the most on the speed of the fan, especially if the fan is only one). The new Scythe Ninja 3 is the best cooler in quiet mode, second to the Mugen 2 rev. B at 1200 RPM and only third at 1900 RPM, falling behind the ThermoLab Baram2010 and the Mugen 2 rev. B. The latter is more effective than the Ninja 3, let alone the Yasya, in two out of the three test modes.

When the tower-design coolers work with two fans, their performance is very similar in every test mode. How can we find the best cooler then? Well, the Rasetsu having defaulted from the race, we can overclock the CPU even more to do that. So, we overclocked our Intel Extreme Edition i7-980X to 4440 MHz at a voltage of 1.45625 volts. We performed the tests with two fans at 1200 and 1900 RPM.

The coolers do not change places here anymore. We’ve got one outsider (Yasya) and two leaders (ThermoLab Baram 2010 and Scythe Mugen 2 rev.B). The new Ninja 3 is in the middle. It is optimized for very quiet modes, so we can’t expect extremely high performance from it. Unfortunately, the Ninja 3 did not cope with our Intel Extreme Edition i7-980X processor at its default frequency without fans under such hot weather (the ambient temperature was as high as 31°C). When we launched 64-bit Linpack, the CPU would get as hot as 86°C in 5 minutes and we had to stop the test to prevent it from getting even hotter. On the other hand, we suspect that the Ninja 3 would be able to cope with its job in fan-less mode if you take a colder CPU or have milder ambient conditions.

Every cooler was tested with Slip Stream 120 Adjustable PWM fans (SY1225SL12HPVC). You can refer to our earlier review for information about this fan’s noise characteristics.

Conclusion

Unfortunately, we cannot say as much praise about the new Scythe Ninja 3 cooler as about the original Ninja released back in 2005. We wouldn’t call the Ninja 3 a failure, though. It is effective at medium and high fan speeds and very effective at low speeds. It is just not the best as the Ninja used to be, which is actually our only gripe about it. The Ninja 3 is a high-quality product, supports all modern platforms and has a reliable fastening mechanism. Its fan speed can be set up flexibly. The downside of the Ninja 3 is that its kit includes only one pair of wire fasteners for a fan. It is also a rather large and heavy cooler. Such minor drawbacks might have been put up with if the Ninja 3 were the best in performance. Alas, the legend has not returned to us today.

As for the other two products from Scythe, the Rasetsu doesn’t show high performance and depends on whether the side panel of the system case has vent holes or not. On the other hand, it is light and rather compact. It is easy to install on multiple platforms and costs less than the other Scythe coolers in this test session (but it is not really cheap). The Mugen 2 revision B is one of the best air coolers available today. Its performance under the extreme conditions of summer heat is comparable to the recently revised ThermoLab Baram (the latter is smaller, lighter and simpler to install, though). Now you don’t have to remove the CPU socket frame to install the Mugen 2 on your mainboard, which had deterred many potential buyers from the earlier version of the Mugen 2. The Mugen 2 revision B still requires some dexterity from the user, though.