An Extreme Tower: Tuniq Tower 120 Extreme Cooler Review

Today we are going to talk about a very interesting and unique cooler using Core-Contact technology (when heatpipes form part of the cooler base).

Almost four years ago the Taiwanese company called Tuniq Co. Ltd., which is a subdivision of Sumbeamtech, announced their Tuniq Tower 120 cooler. This solution won a lot of awards from online and printed publications and earned the well-deserved enthusiasts’ respect and love. Extremely high cooling efficiency of that solution and low level of generated noise at minimal fan rotation speed allowed successful CPU overclocking without making your ears suffer. It was Tuniq Tower 120 that was used to set quite a few overclocking records involving air-cooling.

Time went on, platforms and processors changed, and so did their heat dissipation as well as retention mechanisms. At the same time more and more new air-cooling solutions appeared in the rapidly growing market. The most remarkable one seems to be heat-pipe direct touch technology that is available from many well-known brand names today. The idea behind this technology is that the traditional chain including such links as “processor die → thermal interface → heat-spreader → thermal interface → cooler base plate → thermal glue/soldering → heatpipes” is missing two of them: “cooler base plate → thermal glue/soldering”. Theoretically, in this case the heat transfer and cooling efficiency should improve. Moreover, since the manufacturing process becomes a little simpler and there are no copper base plates involved anymore, the cooler should be cheaper, so that some manufacturers can actually roll out extremely efficient cooling solutions priced below $30.

Tuniq Company decided to keep up with the progress and this summer announced two new cooling solutions: Tuniq Tower 120 Extreme and Tuniq Propeller 120. The second cooler is not yet completely ready to come out, while the first one has already been tested in our lab.

Package and Accessories

The cooler comes in a large box with plastic handle designed primarily with black color scheme with a bit of blue. On the front of the box there are a cooler photo and three pictograms marking the supported key technologies:

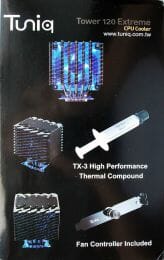

The rest of the cardboard box is also not empty: there is everything you might want to know about the cooler and its accessories:

Inside the colorful cardboard casing there is another box made of thicker denser cardboard that contains a cooler sealed inside a clear plastic blister between two polyurethane foam panels. Beneath the cooler there is a small box with accessories:

Among them are a universal backplate, two retention kits, new Tuniq TX-3 thermal compound, fan rotation speed controller designed as a backpanel bracket and an installation instructions booklet.

Tuniq Tower 120 Extreme is made in China. Its recommended retail price is $59.90. It comes with 3-year warranty.

Design and Functionality

This newcomer is a tower cooler measuring 131×112.3×150.7 mm and weighing 775 g without the fan. Tuniq Tower 120 Extreme looks pretty unusual.

The cooler consists of five copper nickel-plated heatpipes with aluminum nickel-plated plates pressed tightly against them. There are 42 plates with a 29 mm gap in the center for the cooling fan:.

The cooler heatsink is truly unique due to unusual shape of its plates. The plates edges are shaped like blunt cogs of a saw and the plates are slightly shifted away from one another. Therefore, the heatsink looks like fish scales.

Very unique, don’t you think so? But why did they do it this way? There is an opinion that it has been done to lower the airflow resistance and reduce the level of generated noise, but we tend to believe that the “scaled” heatsink design is merely an attraction for potential buyers.

The heatsink plates are 0.4-0.45 mm thick and are spaced out at a little less than 2 mm from one another. The sides of the heatsink are sealed with the plate edges bent downwards.

As I have already mentioned above, the cooler is built on five heatpipes. Three of them are 8 mm in diameter and the remaining two – 6 mm. Note that the heatpipes of different diameter alternate.

The top of the cooler is covered with a decorative cap with a fan attached to it. There is a universal retention plate already attached to the bottom of the heatsink.

The aluminum inserts between the heatpipes in the base of the cooler are only 1.5 mm thick. The contact base surface is very even and is very well finished for a cooler with Core-Contact technology.

Although these imprints look quite different, don’t be surprised. The thing is that we used Tuniq TX-3 thermal compound for the left imprint and Arctic Silver 5 for the right one. However, during our test session the cooler was used with the same Tuniq TX-3 thermal interface on both platforms.

There is a seven-blade 120x120x25 mm fan made of clear plastic inside the Tuniq Tower 120 Extreme heatsink. It is fastened in a metal frame.

You can adjust the rotation speed of this fan using the included variable-speed controller that can be installed on to the back panel of your system case. It allows changing the fan rotation speed from 1000 to 2000 RPM. In this case the fan should generated between 16 and 20 dBA of noise and create 90.65 CFM maximum airflow.

According to the sticker on the fan rotor, it uses a magnetic fluid dynamic bearing (MFDB). Its MTBF is claimed to be 50,000 hours or over 5.7 years of non-stop operation.

The fan rotor is 40 mm in diameter. The fan comes with a 600 mm cable. There are blue LEDs in the corners of the fan frame, which produce very pleasant mild glow in the dark.

However, when the fan is inside the heatsink, you can only see the LED lighting at the bottom of the cooler.

Compatibility and Installation Tips

Tuniq Tower 120 Extreme is a universal cooling solution: it can be installed onto any contemporary platform except LGA1156. Therefore, there is a steel backplate with a sealing pad and holes for mounting spindles.

By the way, the owners of LGA1156 platforms shouldn’t be upset, because Tuniq already has a retention plate for this platform as well, available separately.

To install the cooler on any of supported platforms, you should insert two or four threaded mounting spindles into the retention plate, tighten the screw-nuts on them and place rubber washers on top.

There are separate kits with screw-nuts and washers for Intel and AMD platforms that is why the gap between the backplate and the mainboard PCB will be different for each platform installation.

Once the backplate is in place, you can proceed with the cooler installation onto the CPU. The retention plate is already attached to the cooler base, but you must install two additional retention panels if you work with a Socket AM2(+)/AM3 platform. After that you simply tighten the screw caps with springs evenly.

There is a 45 mm distance between the contact surface of the cooler base and the lowest heatsink plate, however, the lowest edge of the cooling fan is only 30 mm away from the base that is why it wouldn’t let you install memory modules with tall heat-spreaders into the two closest DIMM slots on Gigabyte GA-MA790GP-DS4H (Socket AM2).

You will end up with only one blocked memory DIMM slot (the first one) if you are using Asus P6T Deluxe mainboard (LGA1366). You will have no problems with Tuniq Tower 120 Extreme and memory modules featuring low-profile heat-spreaders or no heat-spreaders at all.

You can always consult a list of guaranteed compatible mainboards on the official company web-site.As for the preferred cooler positioning on the CPU, the manual only mentions it in respect to the LGA1366 platforms and Core i7 processors.

As you see, Tuniq Tower 120 Extreme should be installed so that the heatpipes running through the cooler base covered the most of the processor heat-spreader. Since AMD Socket AM2(+)/AM3 and Intel LGA775 processors have square heat-spreaders, this recommendation doesn’t apply to them.

Testbed and Methods

All the today’s testing participants were benchmarked in two testbeds built with the following components:

- Mainboards:

- ASUS P6T Deluxe (Intel X58 Express), LGA 1366, BIOS 1702;

- Gigabyte GA-MA790GP-DS4H, Socket AM2+, BIOS F7;

- Processors:

- Intel Core i7-920, 2.67 GHz, 1.25V, 4 x 256 KB L2, 8MB L3 (Bloomfield, C0);

- AMD Phenom II X4 965 3.4 GHz, 1.4 V, 4 x 512 KB L2, 6 MB L3, (Deneb, RB-C3);

- Thermal interface: Tuniq TX-3;

- Graphics cards:

- HIS Radeon HD 5850 1024 MB, 725/4200 MHz;

- ZOTAC GeForce GTX 275 896 MB, 633/1452/2268 MHz;

- Memory:

- DDR3 PC3-12800 3 x 2 GB OCZ Platinum Low-Voltage Triple Channel (Spec: 1600MHz / 7-7-7-24 / 1.65 V);

- DDR2 2 x 1 GB CSX DIABLO CSXO-XAC-1200-2GB-KIT (Spec: 1200 MHz / 5-5-5-16 / 2.4 V);

- System HDDs:

- Western Digital VelociRaptor (SATA-II, 300 GB storage capacity, 10,000 RPM, 16 MB cache, NCQ) inside Scythe Quiet Drive 3.5” silencer and cooler chassis;

- Western Digital Caviar Black WD6401AALS (SATA-II, 640 GB, 7200 RPM, 32 MB cache, NCQ);

- System cases:

- Antec Twelve Hundred (front panel: two Noiseblocker NB-Multiframe S-Series MF12-S1 fans at 900 RPM and Scythe Gentle Typhoon fan at 900 RPM; back panel: two Scythe SlipStream 120 fans at 900 RPM; top panel: standard 200 mm fan at 400 RPM);

- Thermaltake Strike MX (two Noiseblocker NB-BlackSilent XL1 fans at 1020 RPM on the bottom front and top back panel; side panel removed);

- Control and monitoring panels:

- Zalman ZM-MFC2;

- Zalman ZM-MFC3;

- Power supply units:

- Zalman ZM1000-HP 1000 W (with a default 140 mm fan);

- Thermaltake Toughpower XT 850 W (with a default 140 mm fan).

During this test session the CPU overclocking was limited by the least efficient cooler in its fan’s quiet mode. AMD processor was overclocked to 4.08 GHz with a multiplier and slight increase in the bus frequency (the Vcore was raised to 1.525 V). Intel processor was overclocked to 3.9 GHz with 21x multiplier and “Load-Line Calibration” enabled. The processor Vcore in this case was increased to 1.34375 V in the mainboard BIOS.

All other parameters available in the mainboard BIOS and connected with CPU or memory overclocking remained unchanged (set to Auto).

All tests were performed under Windows 7 RTM x64 operating system. We used the following software during our test session:

- Everest 5.02.1925b – to monitor AMD CPU core temperature and fans rotation speeds;

- Real Temp 3.39b2 – to monitor Intel processor core temperature;

- Linpack 64-bit with LinX shell version 0.6.4 – to create maximum CPU load for AMD processor (fifteen Linpack runs with 1400 MB RAM capacity involved) and Intel processor (5 Linpack runs with 3584 MB RAM capacity involved);

- RivaTuner 2.24 – to visually control Intel core temperature changes (with RTCore plugin);

- CPU-Z 1.52.2 – to monitor processor core voltages and frequencies.

The CPUs were loaded with two consecutive Linpack test runs with the settings as indicated above. The stabilization period for the CPU temperature between the two test cycles was about 8-10 minutes. We took the maximum temperature of the hottest processor core of the four for the results charts. Besides, we will also provide the detailed temperature readings for all four processor cores together with their average in a separate table. The ambient temperature was checked next to the system case with an electronic thermometer with 0.1 °C precision that allows monitoring the temperature changes over the past 6 hours. During our test session room temperature was at 22.8-23.2 °C.

The noise level of tested coolers was measured after 1:00 AM in a closed room about 20 m2 big using CENTER-321 electronic noise meter. The noise level for each cooler was tested outside the system case when the only noise sources in the lab were the cooler and its fan(s). The noise meter was installed on a tripod and was always at a 200 mm distance from the cooler fan rotor. To measure the noise we set the cooler onto a 45 mm stand made of polyurethane foam material on top of a desk. The lowest noise reading our noise meter device can register is 29.8 dBA and the subjectively comfortable noise level in these testing conditions was around 35 dBA. The fan(s) rotation speed was measured in the entire supported range using our controller by changing the voltage.

Our today’s hero, Tuniq Tower 120 Extreme, will compete against the best cooler with heatpipe direct touch technology – Xigmatek Thor’s Hammer and our reference solution – Thermalright IFX-14 with evened out base. These coolers were tested with one and two Thermalright TR-FDB-2000 fans working in quiet mode at 810 RPM, moderate mode at 1360 RPM and at maximum rotation speed of 2000 RPM.

Besides the tests with its default fan, Tuniq Tower 120 Extreme will also be tested with one and two Thermalright TR-FDB-2000 fans. One of these fans was installed instead of the default Tuniq fan, which the second one was installed on the outside of the heatsink for air exhaust.

That’s pretty much all I could say about our testing methodology for today. Let’s check out the cooling efficiency and acoustic performance of the new solution now.

Cooling Efficiency Tests

Dependence of Cooler Efficiency on Fans Number and Rotation Speed

In this test session the maximum Intel processor frequency was limited by the cooling efficiency of Tuniq Tower 120 Extreme cooler with one default fan at 600 RPM and made 3885 MHz at 1.3375 V Vcore. During the tests with two fans instead of a single default one we used two Thermalright TR-FDB fans. The fan rotation speed was adjusted in 200 RPM increments. The results are given on the chart below.

With one default fan the efficiency of Tuniq Tower 120 Extreme increases linearly as the fan rotation speed rises from 800 to 1600 RPM. The CPU temperature in this range lowers by 16 °C (from 95 to 79 °C). It makes almost no sense to increase the rotation speed over 1600 RPM, because in this case the temperature lowers only by 1 °C.

The results obtained on the new cooler with two fans are pretty interesting. By replacing the default fan with two Thermalright ones allows to lower the peak CPU temperature by 4 °C at the same rotation speed of 600 RPM. At 800 RPM the cooling efficiency improves even more: by 7 °C (from 91 °C to 84 °C) and provides an 11-degree advantage over the single-fan mode at the same speed. Unfortunately, it is impossible to install the second fan onto Tuniq Tower 120 Extreme using standard retention. Further increase in the fans rotation speed produces linear improvement of the cooling efficiency in the interval from 1000 to 1400 RPM, while higher rotation speeds do not really pay back in this Tuniq Tower 120 Extreme configuration.

Cooling Efficiency on Intel Platform

Now let’s check out the performance of Tuniq Tower 120 Extreme and its competitors on an Intel platform at a slightly higher CPU frequency and Vcore.

I have to say that compared with Xigmatek Thor’s Hammer the new cooler did very well. First, it is true about a dual-fan configuration, when Tuniq Tower 120 Extreme turned out 1-2 °C more efficient than the competitor at low and medium fan rotation speeds and lost 1 °C at maximum speed. In a configuration with one Thermalright fan Thor’s Hammer is 1 °C more efficient in all speed modes. The reference Thermalright IFX-14 is much more efficiency than any of the solutions with heatpipe direct touch technology in all speed modes. Here is a table with detailed test results for your reference.

As for the dependence of Tuniq Tower 120 Extreme performance on the way its heatpipes are positioned over the CPU heat-spreader, we can’t draw any interesting conclusions, because multiple tests in different positions didn’t reveal any difference. The results varied within 1 °C that is why I can’t claim that any of the installations is preferable.

Cooling Efficiency on AMD Platform

Let’s see how well Tuniq Tower 120 Extreme will perform in a platform with a significantly overclocked AMD Phenom II X4 processor.

Compared with the previous tests, the results on AMD platform are just a little different. Tuniq Tower 120 Extreme and Xigmatek Thor’s Hammer have very similar cooling efficiency. The former is more efficient with two fans, while the latter – with one. Relatively low heat dissipation of the AMD processor combined with its smaller die doesn’t allow Thermalright IFX-14 to show the same advantage over the competitors as on an Intel platform.

We will not provide the detailed results table here, because the temperatures of all cores were the same.

Acoustic Performance

We tested the acoustic performance of Tuniq Tower 120 Extreme not only with a single default fan but also with a Thermalright TR-FDB fan. The results turned out pretty interesting.

It turned out that the new cooler works quieter with its default fan than with a high-performance Thermalright TR-FDB fan. But the reason is not in the uniqueness or some remarkable qualities of the default cooler fan, but in a successful combination of a heatsink and a fan. Thermalright TR-FDB is noisier because Tuniq Tower 120 Extreme would produce some sort of clinging sound at the same speed (probably because of higher static pressure), which was immediately registered by the noise meter device.

The acoustic readings and our subjective impressions from the cooler allow us to conclude that it is a quiet solution at 1050 RPM fan rotation speed. After that the noise level increases dramatically up until 1250 RPM. After that and until 1630 RPM noise level increases linearly with the fan rotation speed and then makes another significant upsurge in the interval until 1850 RPM. Despite this non-linear increase in the level of generated noise, we didn’t register any crackling of the fan or jingling of the heatsink plates in the entire rotation speed range. The startup fan voltage is 3.2 V and its peak power consumption at maximum speed didn’t exceed 3.5 W.

Conclusion

Although Tuniq Tower 120 Extreme doesn’t work miracles, it boasts very successful combination of features that will definitely be noticed by overclocking enthusiasts. Tuniq Tower 120 Extreme is as efficient as one of the best solutions using heatpipe direct touch technology, and the noise it produces at 1300-1350 RPM remains more than moderate and at 1050 RPM or lower – very quiet. Moreover, the cooler is universal, comes with reliable and convenient retention, uniquely shaped heatsink, beautiful transparent fan with blue LEDs and rotation speed controller, and is accompanied with a tube of new Tuniq TX-3 thermal compound. The recommended retail price of $59.90 is comparable to the price tag of competing solutions that is why I have no doubts that the Extreme Tower will find its niche in the crowded cooling market.

Even with all these advantages in mind, we could like to suggest a few improvements that could make Tuniq Tower 120 Extreme even more efficient and successful. For example, it would be nice to be able to install a second fan for air exhaust and at the same time change the rotation speed range for both fans from the current 1000-2000 RPM to more efficient 600-1600 RPM. I am sure that the cooling efficiency could improve significantly if they made the gaps between the heatpipes in the cooler base even smaller or removed the aluminum inserts completely (coolers like that are already starting to appear). At the same time, it would be good to distribute the heatpipes more evenly over the heatsink body, so that it could be used more effectively. Hopefully, the next model of the Tuniq tower cooler won’t take four years to come out. And as for the new Tuniq Propeller 120 top-cooler, we hope to get our hands on one shortly, so bear with us.