Air Flow: ThermoLab BARAM CPU Cooler Review

The cooler we are going to talk about today seems to be an explosive combination of the latest technologies, as it in fact uses all the best innovative ideas of our times. Let’s find out how efficient this solution is and how far ahead it will get past one of the current super coolers.

The South Korean ThermoLab Co., Ltd founded in the far-away 2003 is not very well-known yet in the cooling solutions market. The company’s primary focus was on research and development, consumer electronics and server coolers, as well as patenting their own inventions. However, they didn’t pay much attention to PC components cooling.

Finally, having created sufficient base, ThermoLab launched two small cooling solutions in 2008: “Nano Silencer” and “Micro Silencer”. They couldn’t boast any outstanding features that could distinguish them among a great variety of coolers already available in this market. However, it was merely a prelude to the arrival of a cooler called “BARAM”, which translates from Korean as “air flow”. The modestly looking cooler boasted a very ambitious specification, namely they claimed that ThermoLab BARAM could cope with up to 250W CPUs! Even the best cooling solutions out there deal with considerably lower numbers (180-200 W), that is why these ambitious claims from a not very known manufacturer make the new cooler even more interesting to us. So, let’s find out if the new cooler is as good as they say it is.

Package and Accessories

The new cooler arrives in a small box designed in the best traditions of Thermalright Company. If you are not very familiar with the Thermalright products, I will have to explain: Thermalright cooling solutions have long been shipping in unimpressive brown boxes with minimum information on them. ThermoLab BARAM is also shipped in a box with ascetically simple design:

One side of the box translates the “BARAM” from the Korean and indicates where the cooler was made. The other side lists all supported processor sockets and mentions the cooler dimensions.

There are two sections inside the box. The heatsink sits in the larger one, while the bundled accessories lie in the small one:

- Backplate for LGA775 mainboards;

- Backplate for Socket AM2(+) mainboards;

- Two steel retention plates for LGA775 mainboards;

- Two retentions for Socket AM2(+) mainboards;

- Several sets of screws;

- Four retention wire clips for two fans;

- A syringe with TL5-H thermal compound (W/m*K);

- Installation instructions (not on the photo above).

The cooler we received doesn’t have retention for the new LGA1366 platform for the getting more and more popular Core i7 processor, however, the appropriate retention kits will most likely be available separately or will come bundled with the cooler by default later on. All well-known cooling solutions makers have already solved this problem one way or another. Another drawback, though less serious one, is the absence of silicon shock absorbing fan strips among the cooler accessories that we have already seen by solutions from Noctua or Thermalright, for instance. Note that ThermoLab BARAM comes without any fans.

Design and Functionality

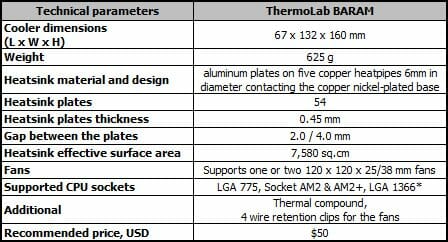

ThermoLab BARAM CPU cooler is a classical representative of the tower heatsinks. It measures 67 x 132 x 160 mm and weighs 625g:

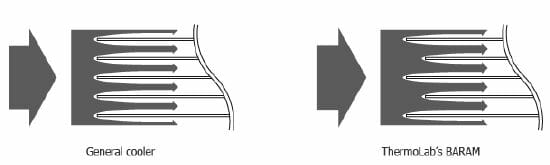

The first thing that immediately catches your eye is the unusual shape of the heatsink plates. Their sides are not straight, but curved. This reduces the airflow resistance, so you can use fans with low rotation speed without losing any of the cooling efficiency.

For the same exact reason the heatsink plates are shifted away from one another:

The heatsink consists of 54 plates and its effective surface measures 7580 sq.cm. Just for your reference: the recently reviewed Zalman CNPS9900 LED has a heatsink with 5402sq.cm surface, and Thermalright Ultra-120 eXtreme is a little bigger – its heatsink surface measures 8050sq.cm. The gap between two symmetrical heatsink plates is 4mm, and between the two closest plates – 2mm. heatsink plates are 0.45mm thick. These aluminum plates are pretty soft, can bend easily, unlike hard heatsink plates of Thermalright Ultra-120 series coolers.

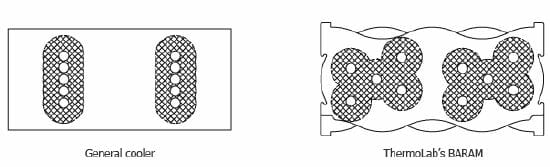

The heatpipes inside ThermoLab BARAM heatsink are arranged in a very smart way, which is another indisputable peculiarity of this solution.

Five copper heatpipes 6mm in diameter pierce heatsink plates not along a single line, which we often see in other coolers, but at 13-mm distance from one another. As a result, the heat flow is distributed more evenly over the heatsink array thus improving the cooler efficiency. This is what it looks like schematically:

I believe that this is a pretty logical solution and it should definitely pay back big.

We have already seen non-linear heatpipes layout in Thermalright Ultra-120 eXtreme heatsink. However, ThermoLab BARAM boasts an even more radical organization.

This is what it looks like on the scheme taken from the manufacturer’s web-site.The cooler base is made of solid copper covered with a thin layer of nickel alloy protecting the copper base against oxidation during long-term use. There are grooves in the base beneath the heatpipes, which should improve the cooling efficiency. However, they are more shallow than the grooves we have seen on other cooling solutions.

The thinnest part of the cooler base measures 4mm. The barely noticeable traces indicate that the heatpipes are in fact soldered to the base. I can’t tell how the heatsink plates are fixed on the heatpipes, however, none of them wiggle or resound during work.

The cooler base boasts the highest quality finish. But most importantly, the base plate is impeccably even: the thermal compound imprint on the glass surface and processor heat-spreader turned out truly immaculate.

You can attach a fan to the heatsink using two wire clips that catch on to the special groove on the side of the heatsink and the retention holes in the fan frame.

Since the heatsink is symmetrical ion length and in width, you can use two 120 x 120 x 25/38 mm fans at the same time. The shock absorbing silicon strips could be a good bonus here, because they are known to lower the fan vibrations received by the heatsink.

Installation Tips

ThermoLab BARAM supports LGA775 and Socket AM2(+) mainboards. The cooler is installed on both these platforms with the retention plates attached with crews to its base.

Then you need to install the cooler onto the board. Unfortunately, installation onto an LGA775 platform is very complicated, because the cooler is attached to the corresponding backplate through the mainboard PCB, but the screws need to be tightened on the other side of the board. In other words, you have to turn the cooler upside down (somehow hold it in place), put the mainboard on top of it, place the backplate to the corresponding holes, insert and tighten the screws.

It is a very hard task for one man, although I did succeed by holding the cooler between my knees. I have no idea why they couldn’t mount the screw-nuts into the backplate and let us tighten the screws from the top rather than bottom of the PCB. It is even more puzzling, because the cooelr is installed very conveniently on top of the board on Socket AM2.

ThermoLab BARAM installed onto the board will not interfere with any components around the CPU socket and tall heatsinks on the chipset and voltage regulator, even though the heatpipes run very close to them.

Take a look at the red washers that I managed to put beneath the steel retention plates while holding the cooler between my legs. They are not included with the accessories; however, I didn’t like the idea of direct contact between the steel retention plates and the mainboard textolite. In other words, LGA775 retention needs to be finished off. Here I also have to add that the distance from the mainboard surface to the lowest heatsink plate of the cooler is 46 mm.

As you see, even with a fan attached to it, the cooler doesn’t interfere with the tall memory heat-spreaders. You can easily add a second fan to the opposite side of the heatsink, if you wish.

Technical Specifications and Pricing

The technical specifications of the new ThermoLab BARAM cooler are summed up in the table below:

Testbed and Methods

We tested ThermoLab BARAM and its competitor in two modes: in a closed system case and in an open testbed. In the former case the mainboard is set vertically and the “tower” coolers are turned horizontally, while in the latter case the mainboard sits horizontally on the desk and the coolers are installed vertically. Our testbed was identical for all coolers throughout the test session and featured the following configuration:

- Mainboard: DFI LANPARTY DK X48-T2RS (Intel X48), LGA 775, BIOS 10/03/2008;

- Processor: Intel Core 2 Extreme QX9650 (3.0GHz, 1.25V, 2x6MB L2 cache, 4x333MHz FSB, Yorkfield, C0);

- Thermal interface: Gelid GC1;

- Graphics card: XFX GeForce GTX 260 (216SP) Black GDDR3 896 MB / 448 bit, 666/1404/2300 MHz;

- Memory:

- 2 x 1024MB DDR2 Corsair Dominator TWIN2X2048-9136C5D (1142MHz / 5-5-5-18 / 2.1V);

- 2 x 1024MB DDR2 CSXO-XAC-1200-2GB-KIT DIABLO (1200MHz / 5-5-5-16 / 2.4V);

- Disk subsystem: Western Digital VelociRaptor (SATA-II, 300GB storage capacity, 10,000RPM, 16MB cache, NCQ);

- HDD silencer and cooler: Scythe Quiet Drive 3.5”;

- Optical drive: Samsung SH-S183L SATA-II DVD RAM & DVD±R/RW & CD±RW;

- System case: ASUS ASCOT 6AR2-B Black&Silver (ATX) with 120mm ~960RPM Scythe Slip Stream 120 fans for air intake and exhaust (the fans are installed on silicon spindles), and Enermax Magma fan at ~960RPM fan on the side panel. We applied noise insulation;

- Control and monitoring panel: Zalman ZM-MFC2;

- Power supply: Thermaltake Toughpower 1500W W0218 (with a default 140 mm fan);

- Monitor: 24″ BenQ FP241W (Wide LCD, 1920 x 1200 / 60 Hz).

All tests were performed under Windows Vista Ultimate Edition x86 SP1. SpeedFan 4.37 was used to monitor the temperature of the CPU and mainboard chipset, reading it directly from the CPU core sensor and to monitor the rotation speed of the cooler fans.

The mainboard’s automatic fan speed management feature as well as CPU power-saving technologies were disabled for the time of the tests in the mainboard BIOS. The CPU thermal throttling was controlled with the RightMark CPU Clock Utility version 2.35.0.

The CPU was heated up in two modes. First we used Linpack 32-bit with LinX shell version 0.5.5. The RAM capacity was set manually at 1600MB and the test cycle included 15 runs.

Since we ran the test twice with 20/10-minute idle period between the runs for the system to cool down and temperatures to set in, the relatively short actual testing period was quite enough for the maximum processor temperature to become stable.

For the second type of load we used OCCT (OverClock Checking Tool) v3.0.0.b23. We ran a 23-minute test with maximum CPU utilization, during which the system remained idle in the first 1 and last 4 minutes of the test.

I performed at least two cycles of tests in both test modes and waited for approximately 15 minutes for the temperature to stabilize during each test cycle. Despite the stabilization period, the result of the second test cycle was usually 0.5-1°C higher. We took the maximum temperature of the hottest processor core after two test cycles for the results charts.

The ambient temperature was checked next to the system case or open testbed with an electronic thermometer with 0.1°C precision that allows monitoring the temperature changes over the past 6 hours. During our test session room temperature stayed at 23.5-24°C. It is used as a starting point on the temperature diagrams. Note that the fan rotation speeds as shown in the diagrams are the average readings reported by SpeedFan, and not the official claimed fan specifications.

We are going to compare ThermoLab BARAM against a known super cooler – Thermalright Ultra-120 eXtreme-1366RT.

Since the new cooler is designed to support only new Core i7 platform, we used the retention kit from the universal modification of the same cooler for our LGA775 platform. We didn’t use the default fan. Both cooling solutions were tested with one and two identical Scythe Slip Stream 120 fans (120 x 120 x 25 mm) in quiet mode at 870RPM and at maximum rotation speed of 1930RPM. The fans were installed for air intake-exhaust.

Cooling Efficiency

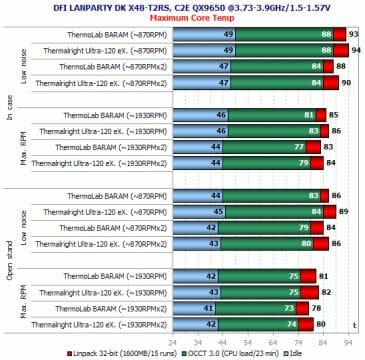

During Linpack tests inside a closed system case using the “weakest” cooling system of the today’s testing participants we managed to overclock our 45 nm quad-core processor to 3.73 GHz (+24.3%). The nominal processor Vcore was increased to ~1.5 V in the mainboard BIOS (+30.4%). During the OCCT tests in the same conditions the CPU remained stable up to 3.9 GHz (+30%) at 1.56V (+35.7%) Vcore.

The obtained results are given on the diagram below (the coolers are grouped according to the testing conditions and noise levels):

Well, ThermoLab BARAM proves to be more efficient on an overclocked processor than its formidable opponent, even though the advantage is relatively small. The newcomer is about 1-3°C better. We remember that Thermalright Ultra-120 eXtreme has been the most efficient tower cooler so far (with the exception of unique Thermalright IFX-14). Also, considering that ThermoLab BARAM is 165g lighter and $15-$20 cheaper, and features an impeccably even base, it has every right to be called the best CPU air cooler! It’s a pity that the advantage is too low and we can’t overclock our processor to a higher frequency than with Thermalright Ultra-120 eXtreme. However, it is in fact quite logical, as the peak temperature difference is too low to affect maximum overclocking result in any way.

We are not going to discuss the acoustic parameters, because both coolers were tested with identical fans already reviewed before.

Conclusion

ThermoLab BARAM cooling solution tested today deserves our best feedback. However, it is not because this cooler managed to slightly outperform the former efficiency leader. Most importantly the manufacturer achieved it not by increasing the size and weight of their solution, but by squeezing everything they could out of a relatively modest-looking heatsink. All the optimizations of the traditional tower heatsink implemented by ThermoLab engineers allowed BARAM to cool the overclocked processor 1-3°C better with 1 less heatpipe, smaller size, lower weight and at a lower cost than the reputed Thermalright Ultra-120 eXtreme. Well, as they say: the king is dead, long live the king!

However, we can’t help pointing out the drawbacks that we discovered during our test session. The biggest problem seems to be the extremely inconvenient installation procedure for LGA775 platform. You will either need an assistant or experience in holding the heatsink with your legs in order to successfully install ThermoLab BARAM onto this platform. We also wish there were a new LGA1366 retention kit and four shock-absorbing silicon strips for the fans included with the cooler. Some potential users may be upset that there are no fans, so I would suggest that ThermoLab should also offer a BARAM modification with two fans besides the current one with only a heatsink. I sincerely hope that the manufacturer will take note of my findings and we will very soon see an even better optimized “air flow”.