Titan Fenrir and Kingwin XT-1264 Coolers Review

We are going to talk about two new coolers with heatpipe direct touch technology, but using heatpipes of different diameter. Read our new review of two new solutions from Titan and Kingwin.

Cooling solutions started moving towards 8 mm heatpipes instead of traditionally used 6 mm ones a while ago – back in the days of Enzotech Ultra-X or first Thermalright SI-128 revisions. At first glance this seemed like a logical solution on the manufacturers’ part, because the effective surface of the 8 mm heatpipes (provided all other conditions are identical) was 33.3% bigger than the effective surface of a 6 mm heatpipes, which should theoretically have positive effect on the efficiency of the heat transfer. However, since processor heat-spreaders are pretty small, you can actually use more 6 mm heatpipes in a heatsink than 8 mm ones and this way partially make up for the difference in the heatpipe diameter. Super-cooler heatsinks are more often built with six 6 mm heatpipes (rarely five), or four 8 mm ones. However, today we are going to compare side by side two cooling solutions with the same number of heatpipes of different diameter. We will talk about Titan Fenrir with four 8 mm heatpipes and Kingwin XT-1264 with four 6 mm heatpipes. This comparison is especially interesting not only because both these cooling solutions cost about the same, but also because both of them use heatpipe direct touch technology, which means that the effect from different heatpipes diameter will be more obvious here, while in traditional coolers it is usually leveled out by the heatsink.

So, let’s get started.

Package and Accessories

Both coolers ship in boxes of about the same size, but the Titan box is made of clear plastic, while the Kingwin one – of cardboard and has a cut-out window in the front.

The technical specifications and key features of both coolers are listed on the back and sides of the boxes. The coolers are bundled with the following accessories:

- Universal retention plate;

- Backplate for LGA1366 mainboards;

- Backplate for LGA775 mainboards and AMD platforms;

- Two wire clips for attaching the fan;

- 4-pin to 3-pin power adapter;

- A set of screws, spindles and screw-nuts;

- Titan Royal Grease thermal paste;

- Installation manual.

- Two retention brackets for LGA1366 mainboards;

- Retention swing-clip for AMD platforms;

- Two retention brackets for LGA775 mainboards;

- Two wire clips for attaching the fan;

- A no-name pack of thermal compound;

- Installation manual.

There is nothing extraordinary about the accessories bundled with these two cooling solutions. We are going to put Titan Royal Grease aside for our upcoming thermal compounds roundup. I only have to add that both cooling solutions are made in China.

Design and Functionality

Now let’s take a closer look at Titan Fenrir and Kingwin XT-1264 coolers:

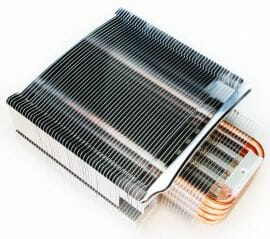

These are coolers of tower topology. Titan solution measured 124x107x156 mm and Kingwin cooler – 120x74x150 mm. They weigh 790 g and 467 g respectively. Each cooler has four heatpipes: 8 mm diameter heatpipes by Titan and 6 mm diameter heatpipes by Kingwin. They are lined up linearly inside the coolers heatsinks:

The heatsink of Titan Fenrir consists of 51 aluminum plates, each 0.5 mm thick. The heatsink plates in the array are spaced out at 2 mm from one another. Kingwin cooler has more plates, there are 60 of them. However, they are thinner (only 0.4 mm) and spaced out at a slightly greater distance from one another: 2.2 mm:

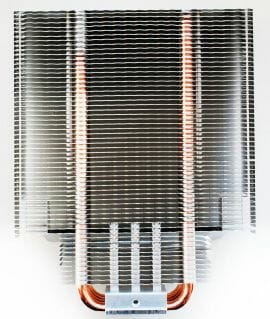

Take a closer look at the top right photo of Kingwin XT-1264: the heatpipes on the left inside the cooler heatsink are about 25 mm shorter than the height of the heatsink, so the top ten heatsink plates simply have no contact with them. The only possible explanation of this fact that I can think of is the manufacturing defect. The sides of the Titan Fenrir heatsink are not covered with anything, while Kingwin XT-1264 has the edges of its heatsink plates bent upwards closing the gaps between the heatsink plates on the sides completely.

The heatsink plates also have different profiles, but it is obvious that both manufacturers tried to lower the airflow resistance. For example, Titan curved the heatsink plates on both sides. While, Kingwin created wave-shaped edges where the airflow from the fan approaches, which also minimized airflow resistance.

The heatpipes coming of the base of Titan Fenrir cooler look quite common, they haven’t been even shifted away from one another. As for Kingwin, even though there are no special optimizations aimed at more even heat distribution over the heatsink, they added an additional heatsink array of 11 small plates at the bottom of the primary heatsink:

As we can see, the engineers did their best to use then entire effective heatpipe surface as effectively as possible. Here you can also clearly see two heatsink plates in the lower part of the Kingwin cooler that are slightly longer than the others and must be designed this way to direct the airflow towards the mainboard electronic components around the processor socket.

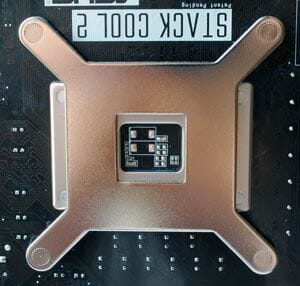

As you can see, the bases are also different. The gap between 8 mm heatpipes in the base of Titan Fenrir cooler measures 1.85 mm, while the 6 mm heatpipes of the Kingwin solution are spaced out at only 1.1 mm from one another. There is an aluminum plate covering the top of the heatpipes in the base that also serves as mounting support.

The finish quality on both bases is very similar and in fact quite common for cooling solutions using heatpipe direct touch. The base surface in both cases is perfectly even.

The thermal compound imprint left by the processor heat-spreader on the base of Titan Fenrir cooler came out quite satisfactory. Unfortunately, we can’t say the same about the imprint on the base of Kingwin XT-1264: it didn’t come out as even as it could have been because of relatively low contact pressure, even though it did cover all the heatpipes in the base.

Titan Fenrir catches your eye with shimmering silverfish fan blades and glossy frame. The Kingwin’s fan looks very simple against the background of the shining competitor, although its sharp blades widened towards the edges and smaller rotor (41 mm in diameter against 44 mm by Fenrir) make Kingwin’s fan more powerful and advanced.

The rotation speed of both fans can be adjusted using pulse-width modulation (PWM) method. As for the declared technical specifications, Titan Fenrir fan supports Titan Fenrir 800-2200 RPM speed range (33.2-78.41 CFM, 17.2-39.0 dBA), and Kingwin XT-1264 fan should work in the 700-2300 RPM interval (82.0-101.2 CFM, 34.5-38.0 dBA). As you can see, both fans support very similar rotation speeds, while the airflow and noise level data seem to be spinned out of thin air (especially Kingwin XT-1264’s numbers).

Both fans use “improved” slide bearings with 60,000 hours declared MTBF.

The claimed current readings are very similar for both fans that is why we can expect them to consume about the same amount of power during work, but we will have to check it out during our test session.

Both fans are attached to the heatsinks using two wire clips. The only difference is that on Titan Fenrir these clips catch on the inside of the fan frame, while on Kingwin XT-1264 – on the outside of the fan frame.

There are no additional clips included with the coolers as well as no mounting space on the cooler heatsink for the second fan.

Installation Tips

Both new coolers can be installed onto any of the contemporary platforms, they come bundled with everything necessary for that. Titan Fenrir is installed through the mainboard PCB with very secure screw-on retention, which is extremely important for cooling solutions using heatpipe direct touch technology.

The only problem here is that you will have to remove the mainboard from the system case in order to install this cooler. As for Kingwin XT-1264, you won’t need to do that, because the cooler installed onto LGA1366/775 platforms with standard plastic push-pins, and onto AMD mainboards – with a traditional swing-clip that catches on to the loops in the default preinstalled retention frame around the processor socket.

The distance from the mainboard to the lowest heatsink plate of Titan Fenrir cooler is about 45-47 mm, which is more than enough to ensure that there won’t be any conflict between the cooler and the heatsinks on mainboard voltage regulator components. Fenrir is also very unlikely to interfere with the memory DIMMs featuring tall heat-spreaders, as it is only 124 mm wide. Kingwin XT-1264 is even narrower (only 120 mm), so there shouldn’t be any problems here either.

There is nothing is manuals about the preferable positioning of the coolers inside the system case, but in our tests both coolers worked more efficiently when they were installed with the airflow directed towards the top of the system case, rather than the back of it (the photo below shows the correct positioning for Kingwin cooler and the incorrect one for Titan).

The temperature difference between two cooler positions made about 3-4 °C.

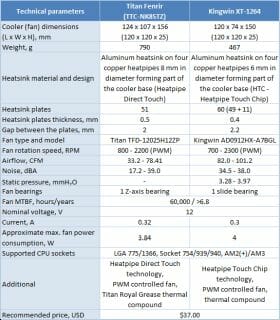

Technical Specifications and Recommended Pricing

In conclusion let us sum up all the technical details about the coolers we have just discussed in the following table:

Testbed and Methods

All tests were performed inside a closed system case. Our testbed was identical for all coolers throughout the test session and featured the following configuration:

- Mainboard: ASUS P6T Deluxe (Intel X58 Express), LGA 1366, BIOS 1606;

- Processor: Intel Core i7-920, 2.67 GHz, 1.25V, 4 x 256 KB L2, 8MB L3 (Bloomfield, C0);

- Thermal interface: Arctic Silver 5;

- Graphics card: ZOTAC GeForce GTX 260 AMP2! Edition 896 MB, 648/1404/2108 MHz (1030 RPM);

- Memory: DDR3 PC3-12800 3 x 2 GB OCZ Platinum Low-Voltage Triple Channel (Spec: 1600MHz / 7-7-7-24 / 1.65 V);

- System HDD: Western Digital VelociRaptor (SATA-II, 300 GB storage capacity, 10,000 RPM, 16 MB cache, NCQ) inside Scythe Quiet Drive 3.5” silencer and cooler chassis;

- Backup HDD: Western Digital Caviar Green WD10EADS (SATA-II, 1000 GB, 5400 RPM, 32 MB, NCQ);

- Optical drive: Samsung SH-S183L;

- System case: Antec Twelve Hundred (front panel: two Noiseblocker NB-Multiframe S-Series MF12-S1 fans at 820 RPM and Scythe Gentle Typhoon fan at 840 RPM; back panel: two Scythe SlipStream 120 fans at 840 RPM; top panel: standard 200 mm fan at 400 RPM at the top of the case);

- Control and monitoring panel: Zalman ZM-MFC2;

- Power supply: Zalman ZM1000-HP 1000 W (with a default 140 mm fan).

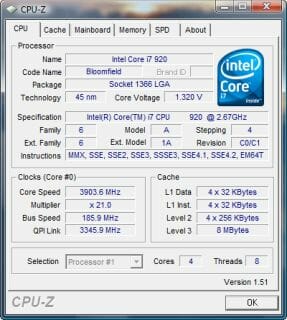

During this test session we managed to overclock our 45nm quad-core processor with the multiplier set at 21x and “Load-Line Calibration” enabled to 3.9 GHz (+46.3%) using the weakest cooling system of the today’s testing participants. The nominal processor Vcore was increased to 1.3125 V (+9.4%) in the mainboard BIOS.

The memory voltage was at 1.62 V and its frequency was 1487 MHz (7-7-7-14_1T timings). All other parameters available in the mainboard BIOS and connected with CPU or memory overclocking remained unchanged (set to Auto).

All tests were performed under Windows Vista Ultimate Edition x86 SP1. We used the following software during our test session:

- Real Temp 3.30 RC10 – to monitor the processor core temperature;

- Linpack 32-bit with LinX shell version 0.6.0.2 – to create maximum CPU load (two test cycles, 15 Linpack runs in each cycle with 1624 MB RAM capacity involved);

- RivaTuner 2.24 – to visually control temperature changes (with RTCore plugin)

- CPU-Z 1.51 – to monitor processor core voltage and frequency.

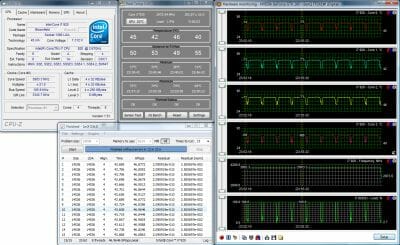

So, the complete screenshot during the test session looks as follows:

The CPU was loaded with two consecutive Linpack test runs with the settings as indicated above. The stabilization period for the CPU temperature between the two test cycles was about 10 minutes. We took the maximum temperature of the hottest processor core of the four for the results charts. The ambient temperature was checked next to the system case with an electronic thermometer with 0.1 °C precision that allows monitoring the temperature changes over the past 6 hours. During our test session room temperature was unusually high and stayed at 26.5-27 °C.

The noise level of each cooler was measured after 1:00 AM in a closed room about 20 m2 big using CENTER-321 electronic noise meter. The noise level for each cooler was tested outside the system case when the only noise sources in the lab were the cooler and its fan(s). I continued to master the noise measuring methodology and decided to install the noise meter on a tripod in order to eliminate possible sound reflection off the desk surface that could affect the readings:

To measure the noise we set the cooler onto a 45 mm stand made of polyurethane foam material on top of a desk and the noise meter was always at a 25 cm distance from the cooler. The lowest noise reading our noise meter device can register is 29.8 dBA and the subjectively comfortable noise level in these testing conditions was at 33.5 dBA. The fan(s) rotation speed was measured in the entire supported range using the new controller revision by changing the voltage in the interval from 3.0 to 12.0 V with 1.0 V increment.

We are going to compare our today’s testing participants against one of the best cooling solutions using heatpipe direct-touch technology – XIGMATEK Thor’s Hammer, and our reference point solution – Thermalright IFX-14. Both these coolers were equipped with two Noiseblocker NB-Multiframe MF12-S3HS fans working in moderate acoustic mode at 1120 RPM and at maximum rotation speed of 1760 RPM. The fans were installed for air intake and exhaust:

We tested the today’s newcomers with the default fans as well as with the same Noiseblocker fans as mentioned above:

Now let’s proceed to the test results and their analysis.

Cooling Efficiency and Acoustic Performance

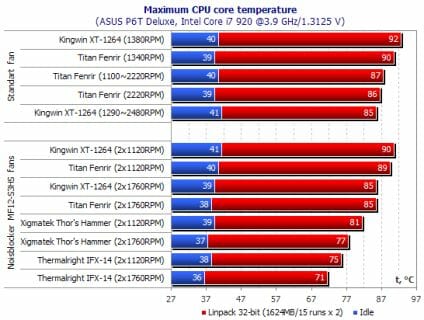

First of all let’s check out the diagram with CPU temperature under different coolers, which will allow us to compare the efficiency of tested solutions. The first group shows the results obtained with standard fans, and the second group – with two Noiseblocker fans:

Judging by the obtained results, we get the impression that Titan Fenrir and Kingwin XT-1264 coolers compete only against one another, because another cooler with heatpipe direct-touch technology participating in our today’s test session – XIGMATEK Thor’s Hammer – is way more efficient, not to mention Thermalright IFX-14. However, we didn’t expect these new solutions to work any cooling wonders here. If we compare the efficiency of a heatpipe direct touch solution using 6 mm heatpipes vs. 8 mm heatpipes, we have to say that bigger heatpipes do not seem to provide any serious advantage. At the same time, it is important to keep in mind that Kingwin’s heatpipes are packed closer together at the base than Titan’s ones, which means that overheated (or unevenly heated) zones under the processor heat-spreader are less likely to occur with Kingwin XT-1264 cooler.

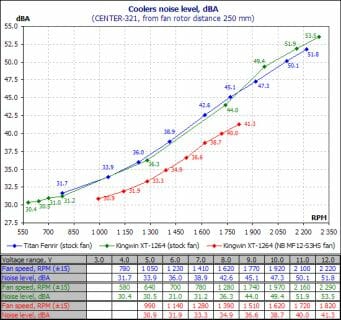

Now let’s take a look at the noise readings in the entire rotation speed range of the default fans. For comparison purposes we have also tested Kingwin XT-1264 cooler with a single Noiseblocker NB-Multiframe MF12-S3HS fan and added the noise readings of this non-standard configuration to the chart:

Both cooler fans turned out pretty noisy not only from our subjective standpoint but also according to the test results. And these are particularly the fans, because when we compared the results with what we got on Kingwin XT-1264 cooler with a Noiseblocker fan, the difference was humongous. Moreover, Kingwin’s fan started to howl very unpleasantly in the interval between 800 and 900 RPM. Titan’s fan, however, generated slight crackling sound up until 1300 RPM speed, which then disappeared in the noise from the fan airflow at higher speeds. Overall, both these fans are very similar in terms of their acoustic performance, except the 1800+ RPM speeds where Kingwin XT-1264 is louder than Titan Fenrir. I would also like to add that Titan’s startup voltage is 4.2 V and maximum power consumption didn’t exceed 3.6 W. Kingwin XT-1264 showed 4.8 V and 3.68 W respectively.

Conclusion

So, what is better: four 6 mm heatpipes or four 8 mm heatpipes? Unfortunately, we couldn’t answer this question today. Frankly speaking, in the course of our review it turned out an impossible question to answer, because for a valid comparison we need two coolers with identical specifications and same number of heatpipes of different diameter. And the coolers we discussed today, Titan Fenrir and Kingwin XT-1264, are not like that, as you already know. So, the question remains open for now.

When we compared two new solutions against one another, it was really hard to pick one favorite, because they demonstrated very similar cooling efficiency and acoustic performance, support the same platforms and sell at the same price. We could say that Titan Fenrir seems a little more appealing because of a remarkable retention solution, but I am sure that some users may not be happy about taking the system apart in order to replace the CPU or processor cooler. Kingwin XT-1264, on the contrary, doesn’t require that. Also, Titan Fnerir has a little more attractive exterior design and comes with Royal Grease paste as a nice bonus. However, Kingwin weighs less. Anyway, I am sure that you will be able to make your choice based on your own needs.